What if your water filter isn’t cleaning your water but contaminating it instead?

Activated carbon is one of the most widely used filtration materials in water treatment. It’s known for its high adsorption capacity, ability to remove odour, colour, and organic impurities, and its essential role in polishing treated water before final use.

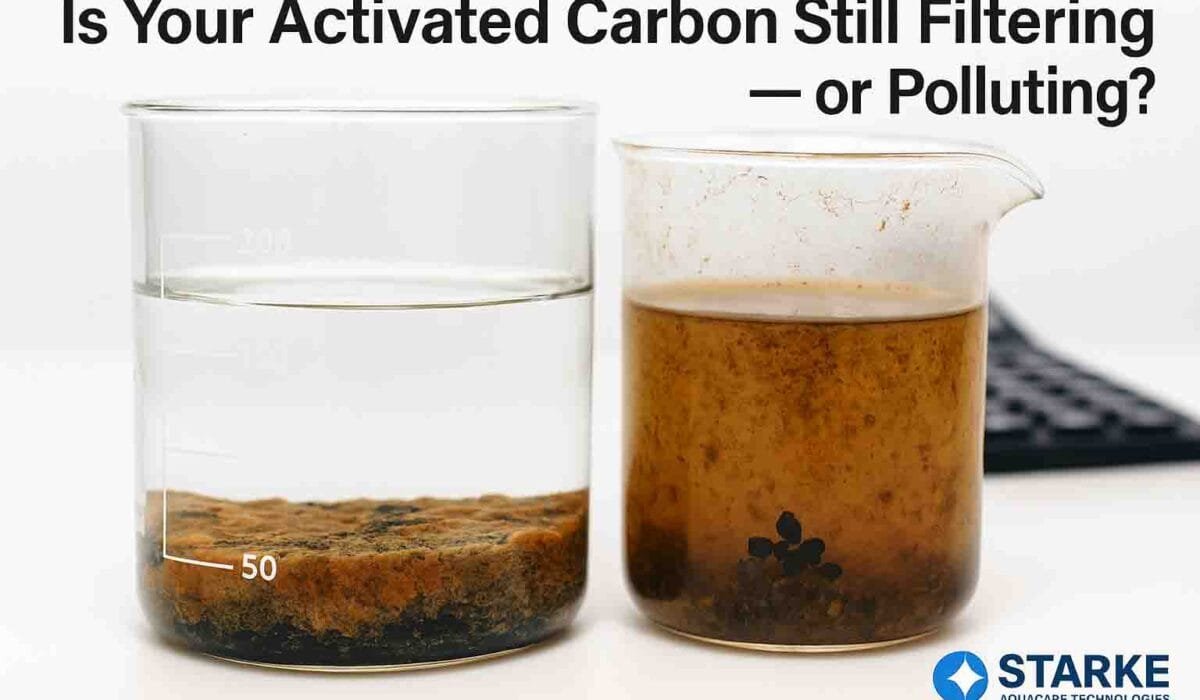

However, when activated carbon becomes spent or fouled, it can transform from a purifier into a pollutant a hidden source of contamination within your filtration system. In recent field studies and lab tests conducted at Starke Aquacare Technologies, spent carbon samples revealed shocking results: rust-coloured sludge, oily films, and bacterial slime formation.

This blog uncovers the real dangers of using spent activated carbon, explains how bacterial iron fouling develops, and highlights why you should always choose virgin activated carbon to ensure safe, consistent water quality.

What Is Spent Activated Carbon?

“Spent activated carbon” refers to carbon media that has already adsorbed contaminants to its full capacity and can no longer effectively remove impurities. Over time, its internal pore structure becomes clogged with:

Dissolved organic compounds,

Oils and hydrocarbons,

Metal oxides like iron and manganese,

Biofilms formed by bacterial growth.

In many filtration systems especially those using groundwater or high-iron sources this fouling process happens faster than operators expect. When maintenance intervals are extended or regeneration is delayed, the carbon bed becomes saturated and starts releasing what it once captured.

The Science Behind the Danger

Activated carbon works by adsorption trapping molecules within its network of micro- and mesopores. But once these pores are blocked or filled with contaminants, water no longer interacts with active sites. Instead, the carbon behaves like an inert carrier, allowing microbial growth and chemical reactions to occur on its surface.

Here’s what typically happens inside a filter with spent activated carbon:

Oxygen depletion: Carbon removes residual disinfectant (chlorine/chloramine), creating a low-oxygen zone.

Microbial colonization: Iron bacteria (Gallionella, Leptothrix, Sphaerotilus) begin colonizing the carbon surface.

Biofilm and slime formation: The bacteria produce extracellular polymers, trapping iron hydroxide and organic matter.

Fouling and release: As the biofilm matures, it starts shedding into the filtrate, carrying bacteria, rust, and odorous compounds downstream.

The result? Your filter now releases contaminants instead of removing them.

Bacterial Iron – The Invisible Culprit

Iron bacteria are naturally occurring microorganisms found in groundwater. They feed on ferrous iron (Fe²⁺) and oxidize it to ferric hydroxide (Fe(OH)₃), forming the characteristic orange-brown slime often seen in fouled filters.

Under a microscope, these bacteria appear as twisted stalks or sheaths. To the naked eye, they produce:

Rust-coloured deposits,

Oily film on the water surface,

Musty or swampy odours,

Sticky clumps coating the carbon granules.

Once established, iron bacteria are extremely difficult to eliminate. They can survive in low-oxygen environments and quickly recolonize after backwashing. Their metabolic by-products can also corrode metal pipes and damage downstream equipment like RO membranes or ion exchange resins.

How to Identify Spent or Contaminated Carbon

Here are some common signs that your activated carbon media has turned toxic:

| Observation | Possible Cause |

|---|---|

| Reddish-brown deposits | Iron or manganese oxide fouling |

| Slimy or sticky texture | Bacterial biofilm |

| Black oily film on surface | Organic or hydrocarbon contamination |

| Musty odour | Anaerobic bacterial activity |

| Cloudy rinse water | Carbon fines release due to structural breakdown |

| Reduced flowrate / high pressure drop | Blocked pores and media compaction |

If your filter exhibits any of these symptoms, it’s time to inspect and replace the carbon immediately.

What Happens When You Keep Using Spent Carbon

Continuing to use spent activated carbon can trigger a chain of failures in your filtration system:

1. Reduced Adsorption Efficiency

Once pores are blocked, adsorption capacity drops by up to 80%. Water may appear clear but still contain dissolved organics, chlorine, or taste- and odour-causing compounds.

2. Microbial Contamination

Biofilms harbor not just iron bacteria but also heterotrophic and sulphate-reducing bacteria. These microorganisms can multiply and enter the treated water, posing health risks.

3. Iron and Colour Bleed

Deposited iron and manganese oxides can slough off during filtration, causing rust-coloured water or staining downstream equipment.

4. Foul Odours and Taste

As the biofilm decays, it releases organic acids and sulphides, resulting in rotten-egg or earthy odours in the treated water.

5. Mechanical Breakdown

Bacterial acids and metal oxides weaken the carbon granules, generating dust and turbidity during backwash.

6. Ineffective Regeneration

Even aggressive acid or steam cleaning cannot fully restore activity once the carbon is biologically fouled.

Ultimately, what remains is not an adsorbent it’s a bacterial incubator inside your filter vessel.

Why Regenerated Carbon Isn’t a Safe Alternative

Some suppliers offer “regenerated” or “rewashed” activated carbon as a cost-effective solution. But in practice, regeneration rarely restores original performance.

During regeneration:

Thermal treatment removes volatile organics but not heavy metals or biofilm residues.

Acid washing may dissolve some iron but can damage the pore structure.

Rewashed carbon still carries biological contamination.

In many cases, regenerated carbon looks clean but performs poorly. Worse, it may introduce bacteria and dissolved metals into new systems.

When compared with virgin activated carbon, regenerated media shows:

30–50% lower iodine number,

Higher ash content,

Uneven grain structure and fines generation.

Therefore, for drinking water and critical industrial applications, Starke strongly advises using only virgin-grade activated carbon to ensure full adsorption capacity and microbial safety.

Real-World Case: When Filters Became Polluters

During a recent client inspection, Starke’s lab team received a batch of spent activated carbon samples from a large commercial water treatment plant. The operator reported frequent odour complaints and reddish water after filtration.

When the sample was immersed in clean water for analysis, the results were revealing:

The beaker turned orange-brown within minutes due to bacterial iron release.

A black oily layer appeared on the surface organic fouling.

The water emitted a musty smell, typical of microbial decay.

This simple jar test visually confirmed what often goes unseen inside full-scale filters: fouled carbon acting as a source of contamination.

Preventive Measures and Best Practices

To maintain consistent water quality and prevent fouling, Starke Aquacare recommends the following preventive actions:

1. Scheduled Carbon Replacement

Replace activated carbon based on service life, not just flow hours. Typical replacement intervals:

Drinking water: every 6–12 months

Industrial process water: 6–9 months

Wastewater polishing: 3–6 months

2. Pre-Filtration

Install iron and manganese removal filters (e.g., Starmnox™, Purozite™, or Manganese Greensand) upstream of carbon filters to prevent metal oxide deposition.

3. Maintain Disinfectant Residual

Ensure a minimal chlorine residual (0.2–0.5 mg/L) before the carbon filter to control bacterial regrowth.

4. Proper Backwashing

Perform periodic backwashing with clean water or mild oxidants (like hydrogen peroxide) to remove trapped biofilm and debris.

5. Regular Microbial Monitoring

Test filtered water for total plate count (TPC) and iron bacteria presence at least once every quarter.

6. Use Only Virgin Activated Carbon

Always source carbon from trusted suppliers that meet AWWA, NSF, and ISO standards. Virgin carbon ensures:

High iodine number (>900 mg/g),

Low ash and moisture content,

Consistent granule hardness,

No biological contamination.

Why Choose Starke Virgin Activated Carbon

At Starke Aquacare Technologies, we specialize in premium-grade coal-based and coconut-shell activated carbon, designed for high adsorption efficiency and long service life.

Our virgin carbon is:

Virgin material and dust-free,

Tested for NTU, pH, bulk density, and iodine number,

Certified under AWWA-B604 and NSF/ANSI standards,

Supplied in moisture-proof packaging with full COA and lab test reports.

We don’t just sell carbon we ensure it performs consistently in real-world water treatment systems.

The Takeaway

Spent activated carbon can silently compromise your filtration system.

What was once a purifier can easily become a pollutant releasing iron, odours, and bacteria back into the water.

Replacing fouled or regenerated carbon with high-quality virgin activated carbon from Starke ensures:

Reliable adsorption performance,

Long filter life,

Microbiologically safe water,

Lower maintenance and downtime.

When it comes to water purification, there’s no shortcut for quality.

Ready to Replace Your Spent Activated Carbon?

Contact Starke Aquacare Technologies today to get a customized quotation for virgin activated carbon suited for your filtration system.