Filter gravel plays a critical yet often underestimated role in water filtration systems. While sand, anthracite, or activated carbon usually receive most of the attention, filter gravel is the foundation that supports the entire filtration bed. Without properly graded and high-quality filter gravel, even the best filter media will fail to deliver consistent performance.

In this detailed guide, we explain what filter gravel is, why it is essential, how it works, grading and layer design, standards, and applications across water treatment systems with practical insights for engineers, EPC contractors, and water treatment operators.

What Is Filter Gravel?

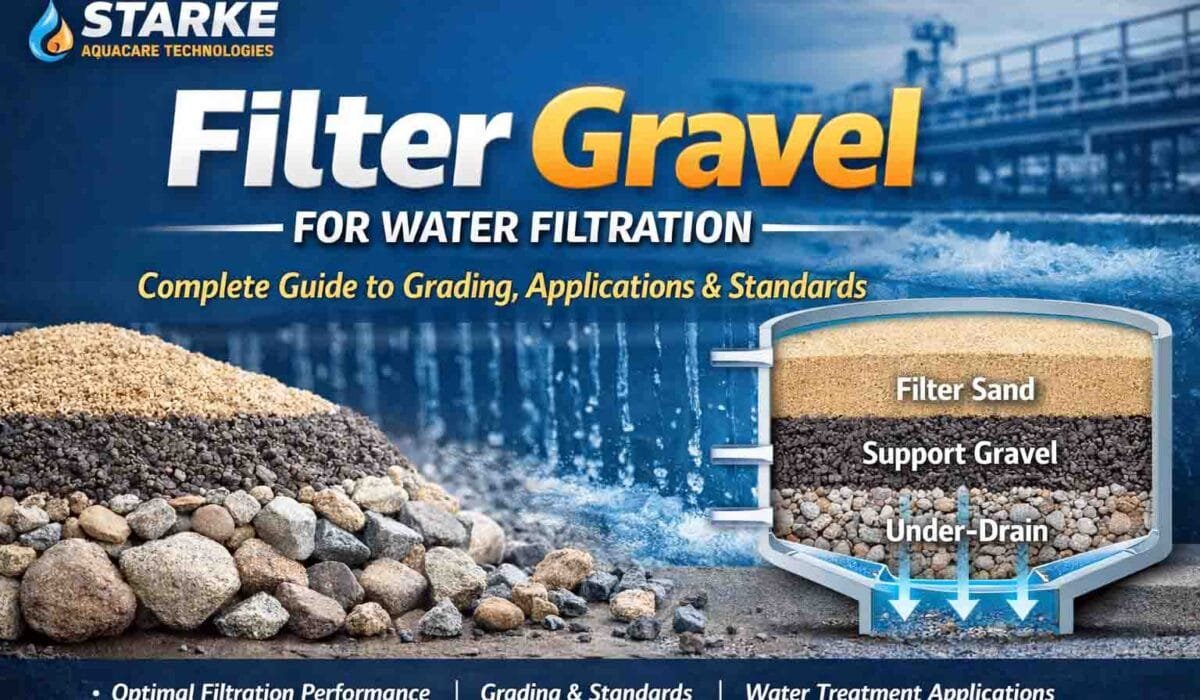

Filter gravel, also known as supporting gravel or filter media gravel, is a carefully graded granular material installed at the bottom of filtration systems. Its primary purpose is to:

Support the active filtration media (sand, anthracite, carbon, etc.)

Prevent media loss into the under-drain system

Enable uniform water flow during service and backwash cycles

Unlike construction gravel, water filter gravel is chemically inert, mechanically strong, and precisely graded to meet filtration standards.

Why Filter Gravel Is Essential in Water Filtration

Many filtration failures can be traced back to incorrect gravel selection or improper layering. High-quality filter gravel improves:

1. Flow Distribution

Gravel creates a stable base that ensures uniform water distribution across the filter bed, preventing channeling and dead zones.

2. Backwash Efficiency

Properly graded gravel allows efficient bed expansion during backwash, helping release trapped suspended solids and restoring filtration efficiency.

3. Media Protection

It prevents fine filter sand or media from entering the under-drain system, avoiding blockages and costly maintenance.

4. Extended Filter Life

A well-designed gravel support layer reduces mechanical stress on the filtration media, increasing service life.

Composition & Material Properties of Filter Gravel

High-performance water filter gravel must meet strict physical and chemical criteria.

Typical Composition

High-purity silicon dioxide (SiO₂) (usually > 95%)

Minimal clay, silt, and organic impurities

Negligible soluble salts

Key Physical Properties

High mechanical strength

Rounded to sub-rounded grain shape

Low solubility in acids

Excellent hardness and abrasion resistance

Quartz gravel is widely preferred because of its chemical inertness and durability.

Filter Gravel Grading & Particle Size Ranges

Correct grading is the backbone of an efficient filtration bed.

Common Filter Gravel Sizes

3 – 6 mm

6 – 12 mm

12 – 20 mm

20 – 40 mm (for large rapid gravity filters)

Grading is designed so that each layer supports the one above it, ensuring smooth transition and preventing media migration.

Sieve Analysis & Uniformity

Controlled particle size distribution

Uniformity coefficient (UC) typically ≤ 1.7

Minimal fines below specified limits

Typical Gravel Layer Arrangement in Filters

A standard filtration system uses multi-layer gravel support:

| Layer Position | Size Range | Function |

|---|---|---|

| Bottom Layer | 20–40 mm | Supports under-drain |

| Middle Layer | 12–20 mm | Transition layer |

| Upper Gravel | 3–6 mm / 6–12 mm | Supports filter sand |

Layer thickness varies depending on filter size, flow rate, and system design but usually ranges from 300 to 450 mm total gravel depth.

Filter Gravel vs Filter Sand: Understanding the Difference

Although often confused, filter gravel and filter sand serve different purposes:

| Aspect | Filter Gravel | Filter Sand |

|---|---|---|

| Function | Structural support | Active filtration |

| Grain Size | Coarse | Fine |

| Location | Bottom layers | Top filtration layer |

| Filtration | No direct filtration | Removes suspended solids |

Both must work together for optimal filtration performance.

Standards for Filter Gravel

Quality filter gravel must comply with recognized standards to ensure safety and performance.

Commonly Followed Standards

IS 8419 (India) – Filter media for water treatment

AWWA B100 (reference for media grading)

EN standards for filtration materials

Compliance ensures:

Safe use in drinking water

Consistent grading

Chemical stability

Applications of Filter Gravel

Filter gravel is widely used across multiple water treatment applications:

1. Drinking Water Treatment Plants

Supports rapid gravity filters and pressure filters for municipal water supply.

2. Wastewater Treatment

Used in tertiary filtration systems to improve turbidity reduction and protect downstream processes.

3. Industrial Water Treatment

Critical in pre-treatment systems for boilers, cooling towers, and process water.

4. Pool & Spa Filtration

Acts as a support layer beneath pool filter sand for even flow and backwash.

5. RO & Desalination Pretreatment

Improves suspended solids removal and protects membranes.

Common Problems Caused by Poor-Quality Filter Gravel

Using non-standard or improperly graded gravel can lead to:

Media loss during backwash

Uneven flow distribution

Filter bed instability

Reduced filtration efficiency

Frequent shutdowns and maintenance

This is why filter gravel selection is a design decision not a cost-cutting item.

How to Select the Right Filter Gravel

When selecting gravel filter media, consider:

Compliance with IS / AWWA standards

Verified sieve analysis

Low clay and fines content

Clean, washed, and kiln-dried material

Consistent bulk density

Always request test certificates and grading data from the supplier.

Why Engineers & EPC Contractors Trust Starke Aquacare Technologies

At Starke, filter gravel is manufactured and supplied specifically for water filtration applications, not general construction use. Each batch is:

Precisely graded

Washed and free from impurities

Tested for physical and chemical properties

Supplied with full documentation

Starke supplies filter gravel, quartz sand, anthracite, activated carbon, garnet, and specialty media for domestic and export water treatment projects worldwide.

Conclusion

Filter gravel may sit at the bottom of a filtration system, but its importance is right at the top. From supporting filter media to ensuring long-term system performance, high-quality filter gravel is essential for reliable and efficient water treatment.

Choosing the right filter gravel size, grading, and standard-compliant material protects your investment and ensures consistent water quality for years to come.

Contact Starke – Filter Gravel & Water Filtration Media Supplier

📞 Phone: +91 7070704639

📧 Email: info@starkefiltermedia.com

🌐 Website: https://www.starkefiltermedia.com