Introduction

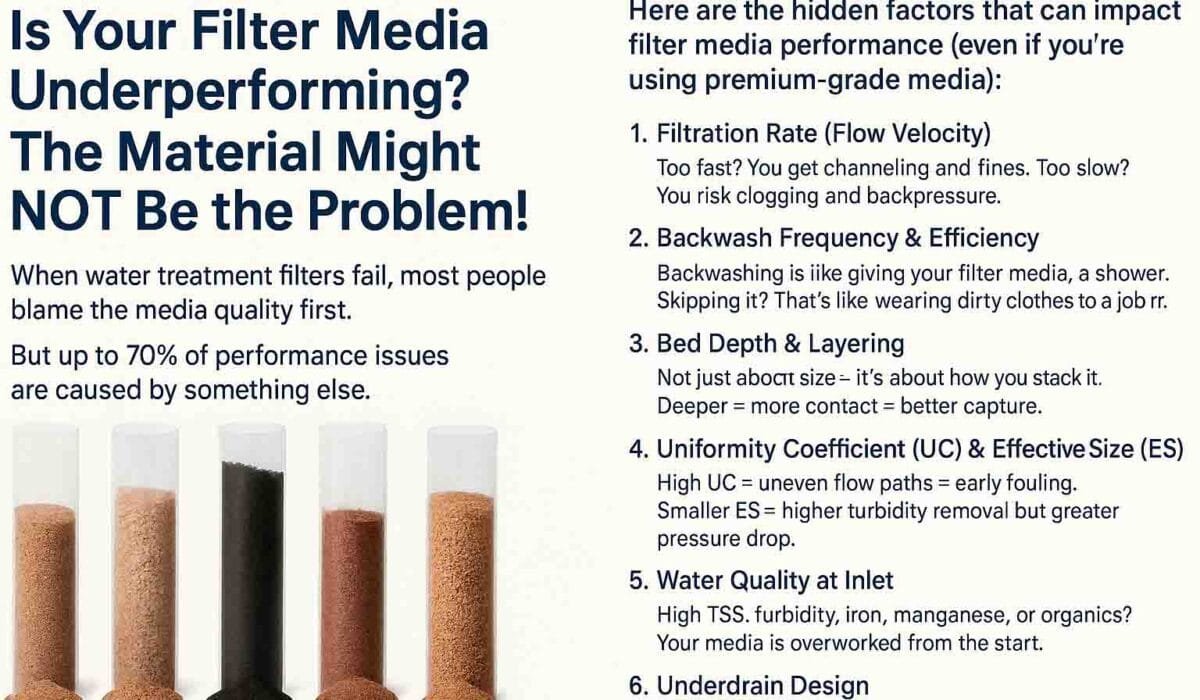

When a filtration system starts to underperform, the filter media often gets blamed. Whether it’s sand, anthracite, activated carbon, or zeolite the assumption is that poor-quality media is at fault.

But the truth is, up to 70% of filtration issues are caused by factors other than the media itself.

At Starke Filter Media, we’ve worked with thousands of municipal, industrial, and commercial water treatment plants. Our data, field audits, and client experiences point to a set of hidden performance factors that are often overlooked yet critical.

In this blog, we uncover the 8 key parameters that influence filter media performance (even when you’re using premium-grade materials), and how to troubleshoot them for better water quality and longer filter life.

1. Filtration Rate (Flow Velocity)

Flow rate directly affects how well your filter media works. If the filtration velocity is too high, water rushes through the bed, causing channeling, media displacement, and inadequate particle capture. On the flip side, too low a flow causes excessive pressure drop, clogging, and reduced cycle time.

📊 Ideal Filtration Rate (for sand media):

Gravity filters: 5–15 m/h

Pressure filters: 8–12 m/h

Solution:

Optimize system design or valve control to maintain stable, recommended filtration velocities across all filters.

2. Backwash Frequency & Efficiency

Backwashing is not just a routine step it’s essential maintenance. Think of it like giving your filter media a deep clean. Inefficient or delayed backwash leads to fouling, media compaction, and clogged pores that reduce permeability and flow.

⚠️ Symptoms of poor backwash:

Rapid pressure increase

Short filter run cycles

Uneven media bed surface

Solution:

Use air + water backwash, maintain recommended backwash flow rates (typically 15–25 m/h for sand), and automate based on DP (differential pressure) triggers.

3. Bed Depth & Media Layering

More depth = more contact time.

A common misconception is that media size matters more than bed configuration. But improper layering or shallow beds result in early breakthrough, ineffective TSS removal, and shorter filtration cycles.

📏 Minimum Recommended Bed Depths:

Single-media sand filter: 600 mm

Dual-media (anthracite + sand): 1000 mm

Multimedia: up to 1200–1500 mm

Solution:

Ensure correct layer sequencing, media separation, and compaction control during loading. Periodically inspect for layer mixing.

4. Uniformity Coefficient (UC) & Effective Size (ES)

Two often-ignored specifications – UC and ES – greatly impact flow uniformity and particle capture.

High UC (>1.7): Uneven flow paths, channeling, and fouling

Low UC (1.3–1.6): Balanced flow and effective filtration

ES (Effective Size): Determines particle capture threshold

Example:

0.45–0.7 mm sand: Fine filtration

0.8–1.2 mm: General-purpose

1.5–2.5 mm: Support gravel layer

Solution:

Always test UC and ES during media procurement. Starke supplies media with controlled grading and certified sieve analysis to ensure optimal performance.

5. Water Quality at Inlet

Even the best media can fail if inlet water quality is too poor.

⚠️ Key contaminants that stress the media:

High TSS (Total Suspended Solids)

Iron & Manganese

Oils or organics

Coagulant carryover (alum/ferric)

Biological growth

These overload the media bed, reduce service life, and cause rapid fouling.

Solution:

Implement or optimize pretreatment steps like:

Sedimentation

Coagulation-flocculation

Oil skimming

Strainers/screens

6. Water Temperature

This is often overlooked. Colder water increases viscosity, slowing down filtration rates and increasing the potential for clogging. It’s like trying to filter honey instead of water.

📉 Filtration performance drops 5–10% for every 10°C drop in temperature.

Solution:

Adjust flow rate for seasonal variations

Choose media with better porosity for colder climates (e.g., dual media with anthracite)

7. Underdrain System Design

Your filter’s underdrain system plays a crucial role in flow uniformity and media retention. A poor design can cause:

Dead zones

Media loss through the nozzles

Uneven backwash distribution

⚠️ Symptoms:

Media seen in outlet water

Uneven surface after backwash

Localized fouling or clogging

Solution:

Use AWWA-compliant underdrains, maintain nozzle integrity, and ensure even hydraulic distribution. Avoid design shortcuts in pressure filters.

8. Pretreatment Quality

If your pretreatment isn’t working, the media will bear the brunt — leading to:

Frequent clogging

Short filter runs

Higher turbidity in filtered water

Common upstream mistakes:

Skipping flocculation

Poor pH control

Using incompatible chemicals

Solution:

Audit your coagulation, flocculation, sedimentation, and chemical dosing systems. Proper pretreatment is the best gift you can give your media bed.

Bonus Tip: Media Handling & Storage

Even before installation, filter media performance can suffer if it’s:

Exposed to moisture during storage

Mixed improperly on site

Damaged due to rough handling

Always store media in dry, covered areas, and ensure correct layering and top-down filling during filter installation.

How Starke Filter Media Helps

At Starke Filter Media, we go beyond just supplying high-quality media. We work with clients to:

Diagnose performance issues

Recommend corrective actions

Customize filter media layering

Ensure compliance with AWWA B100 and NSF standards

We manufacture and export media like:

Filter Sand (0.45–0.7 mm, 0.8–1.2 mm)

Anthracite (0.9–1.1 mm)

Manganese Dioxide for Iron Removal

Garnet, Gravel, Activated Carbon

Zeolite replacement media: PUROZITE™

Our commitment: Helping you get maximum life and performance from your filtration system.

Final Thoughts

If your filter media isn’t delivering results don’t replace it blindly. Audit the system. Check the flow rate, backwash setup, media layers, inlet water quality, and underdrain.

Often, small adjustments can extend filter life by 25–40% and improve output water quality drastically.

💬 Need help?

📩 Reach out for a free consultation or request a media sizing and compatibility guide from our team.