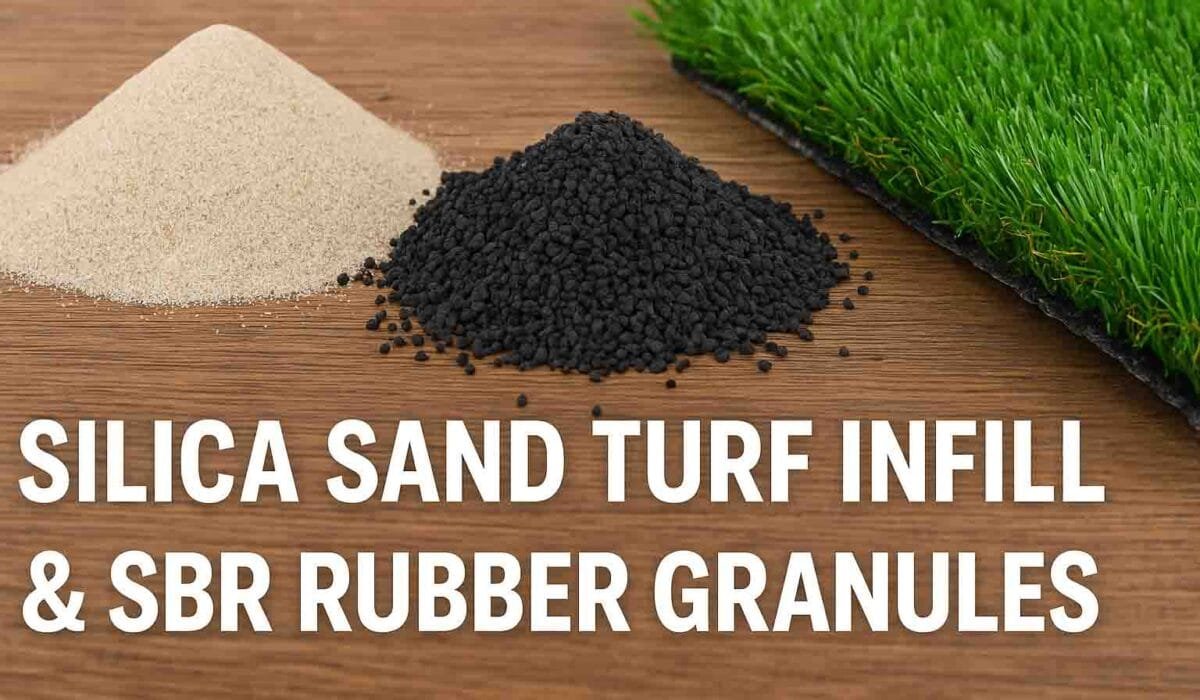

Artificial turf systems have transformed modern sports fields, playgrounds, and landscaping projects. At the heart of these systems lies a critical component that determines their longevity, playability, and safety turf infill. Among the various materials used, silica sand turf infill and SBR rubber granules stand out as the most widely accepted and effective options worldwide.

In this comprehensive guide, we’ll explore everything about silica sand and SBR rubber granules, including their composition, applications, benefits, and why their correct combination ensures optimal performance for synthetic turf installations.

1. What Is Turf Infill and Why It Matters

Infill is the granular material applied between the blades of artificial grass to provide weight, stability, cushioning, and support. It keeps the turf upright, enhances durability, and improves drainage. Without proper infill, the turf can flatten, wear unevenly, and lose its natural appearance.

The two most popular infill materials are:

Silica sand infill for artificial grass

SBR rubber granules (Styrene Butadiene Rubber)

These two materials complement each other silica sand provides structure and ballast, while SBR rubber adds resilience and shock absorption.

2. Understanding Silica Sand Turf Infill

Composition and Properties

Silica sand is a naturally occurring mineral composed primarily of quartz (SiO₂). For turf applications, it is carefully washed, dried, and graded to a specific grain size (typically 0.5–1.0 mm), ensuring consistency and safety.

Key characteristics of silica sand for turf:

High silica purity (above 95%)

Angular to sub-rounded particle shape

Kiln-dried for dust-free installation

Neutral pH and non-toxic

Excellent compaction and drainage properties

Common Mesh Sizes Used

Typical grades include:

0.5–1.0 mm silica sand turf infill for artificial lawns

0.7–1.2 mm silica sand for football and multipurpose sports fields

1.0–2.0 mm silica sand for golf course bunkers and landscaping applications

3. Benefits of Using Silica Sand in Artificial Turf

Stability and Ballast: The uniform grain size of kiln-dried silica sand infill prevents turf movement and curling under foot traffic.

Improved Drainage: The voids between sand particles allow quick percolation of rainwater, maintaining field usability even after heavy rain.

Blade Support: The silica particles keep synthetic turf fibers upright, giving a natural, lush appearance.

Heat Regulation: Natural quartz reflects heat better than black rubber, helping reduce surface temperatures during hot weather.

Low Maintenance: Silica sand infill resists compaction and doesn’t degrade easily, extending the life of the turf system.

Cost-Effective and Readily Available: As a naturally abundant mineral, silica sand for turf infill is budget-friendly and suitable for large-scale projects.

4. What Are SBR Rubber Granules?

SBR (Styrene-Butadiene Rubber) granules are made from recycled automobile tyres through mechanical shredding and cleaning. These black SBR rubber crumb granules range in size from 0.5 mm to 4 mm, depending on the application.

Physical and mechanical properties:

High elasticity and resilience

Excellent shock absorption

Weather and UV resistance

Non-toxic and environmentally friendly when processed properly

5. Applications of SBR Rubber Granules

SBR granules are used across multiple industries and sports infrastructure:

Artificial turf infill for football, hockey, and rugby fields

Playground flooring and safety tiles

Athletic running tracks

Equestrian arena surfacing

Rubberized asphalt modification

Shock-absorbing base layers beneath EPDM coatings

For turf systems, SBR rubber infill is applied on top of the silica sand layer to enhance cushioning, performance, and athlete safety.

6. Why Combine Silica Sand and SBR Rubber Infill

The perfect artificial turf surface isn’t achieved by one material alone. It’s the combination of silica sand turf infill and SBR rubber granules that delivers optimal results.

| Property | Silica Sand Turf Infill | SBR Rubber Granules |

|---|---|---|

| Function | Structural ballast and stability | Cushioning and shock absorption |

| Appearance | Natural white to beige | Black or colored |

| Density | 1500–1600 kg/m³ | 500–600 kg/m³ |

| Position in Turf | Lower layer | Upper layer |

| Temperature Effect | Cooler | Warmer |

| Maintenance | Low | Moderate |

When layered correctly silica sand at the bottom and SBR granules above the turf achieves:

Enhanced shock absorption and energy restitution

Excellent drainage and dimensional stability

Reduced surface heat and player fatigue

Extended system lifespan

7. Optimal Ratios and Installation Tips

For sports turf applications, the typical installation involves:

60–70% silica sand infill (by weight)

30–40% SBR rubber granules

The silica sand layer provides firm support, while the rubber layer enhances comfort and safety.

Example for a football field:

Sand infill depth: 15 mm (25 kg/m²)

SBR rubber granules depth: 10 mm (15 kg/m²)

Tips for installation:

Always use kiln-dried silica sand to prevent clumping.

Apply infill gradually in multiple passes.

Use a power broom for even distribution.

Ensure proper drainage base to prevent waterlogging.

Verify rubber granule size uniformity (1–3 mm ideal for turf infill).

8. Environmental and Safety Aspects

Both materials, when sourced from quality manufacturers, are safe and eco-friendly.

Silica Sand: Chemically inert and non-toxic. It should be washed and dust-free to meet AWWA B100 / EN 12904 purity standards.

SBR Rubber Granules: Produced from cleaned and shredded tyres; modern facilities ensure removal of metals and fibers to meet EN 15330-1 standards for sports fields.

For additional sustainability, Starke also offers consultation on alternative eco-infill materials like coated sands or organic options but for most climates, silica + SBR remains the most reliable, cost-effective solution.

9. Global Applications and Industry Standards

Silica sand and SBR rubber infill systems are used in:

FIFA-approved football fields

World Rugby certified grounds

IAAF athletics tracks

Municipal playgrounds

Landscaping projects and residential lawns

Relevant Standards

FIFA Quality Programme for Football Turf

EN 15330-1 Synthetic turf surfaces

ASTM F2765 / F1936 Shock Absorption and Rotational Resistance

By following these standards, project owners ensure safety, performance, and durability.

10. Choosing the Right Supplier for Silica Sand and SBR Rubber Granules

Selecting a reliable supplier is crucial to project success. Look for:

Consistent grain size distribution and moisture control

Laboratory testing for bulk density and purity

Proper packaging (25 kg bags or 1-ton jumbo bags)

Export experience and logistics support

Technical data sheets and MSDS documentation

Starke Aquacare Technologies, established in 2005, is a trusted global supplier of filtration and turf media exporting silica sand, SBR rubber granules, and other specialty materials to more than 20 countries including the Middle East, Europe, Africa, and Asia-Pacific.

11. Maintenance and Longevity Tips

Routine Brushing: Keeps fibers upright and infill evenly distributed.

Top-Up Infill: Over time, some infill may migrate replace as needed.

Drainage Inspection: Ensure base layers remain unclogged.

Surface Cleaning: Use mild detergents or air blowers to remove debris.

Monitor Granule Condition: Replace when SBR crumb begins to harden or lose elasticity.

Proper care extends turf life beyond 8–10 years, ensuring consistent player safety and aesthetics.

12. The Cost-Efficiency Advantage

Silica sand and SBR rubber infill systems offer unmatched cost-to-performance ratio:

Low installation cost compared to EPDM or coated alternatives

Easy availability and fast delivery

Suitable for both sports turf and residential landscaping

For developers managing large stadium or school projects, this combination delivers FIFA-grade performance at a fraction of the cost of imported infills.

13. Future Trends: Coated and Colored Rubber Infill

While traditional black SBR granules remain dominant, the industry is gradually shifting toward:

Green or grey-coated SBR rubber to reduce surface heat

Silane-treated silica sands for better hydrophobic properties

Hybrid infills mixing cork, sand, and rubber for sustainability

Starke continues to innovate and adapt its product portfolio to meet these evolving standards while maintaining affordability and reliability.

14. Export Packaging and Logistics

Silica sand turf infill and SBR rubber granules are packed in:

25 kg laminated PP bags for retail and project sites

1 ton jumbo bags for bulk export

Optional palletized shrink-wrapped packaging for container shipping

With efficient loading patterns (20–25 tons per 20-ft container), Starke ensures optimal freight utilization and minimal handling loss.

15. Why Choose Starke Aquacare Technologies

Two decades of experience in mineral processing and sports surface materials

Global export capability with deliveries across the Middle East, Africa, and Europe

Quality assurance per EN 12904 / ISO 9001 / AWWA B100

Technical guidance for selecting the right size and combination

Dedicated after-sales support for installation and maintenance

Whether you’re building a football field in Oman, a school playground in Kenya, or a landscaped lawn in Singapore, Starke ensures you receive consistent, tested, and certified infill materials every time.

16. Conclusion

The combination of silica sand and SBR rubber granules has proven to be the most dependable and economical choice for synthetic turf installations worldwide. Silica sand offers strength, structure, and drainage, while SBR rubber provides cushioning, comfort, and shock absorption together delivering high performance, durability, and safety.

When sourced from a trusted manufacturer like Starke Aquacare Technologies, you can be confident of:

High-purity silica sand turf infill with consistent grading

Durable SBR rubber granules made from quality recycled material

Reliable exports, documentation, and customer support

You can purchase high-quality silica sand and SBR rubber granules for sports, landscaping, and turf applications directly from Starke Aquacare Technologies.