Filter sand media is one of the most widely used filtration materials in water and wastewater treatment systems. Despite the availability of advanced filter media, properly selected and graded filter sand remains the foundation of reliable filtration across municipal, industrial, and commercial applications.

However, not all sand is suitable for filtration. Performance depends heavily on particle size distribution, effective size (ES), uniformity coefficient (UC), purity, and operating conditions. Incorrect selection or poor-quality sand media often leads to filter failure, channeling, excessive pressure drop, or frequent backwashing.

This guide explains what filter sand media is, how it works, how it is specified, and how to select the right sand media for long-term filtration performance.

What Is Filter Sand Media?

Filter sand media is a processed, graded, and washed silica-based material used in filtration systems to remove suspended solids from water.

Unlike natural or construction sand, filter sand is:

Carefully graded

Free from clay, silt, and organic matter

Mechanically strong

Chemically stable in water

Filter sand media works primarily through mechanical straining, sedimentation, and surface adsorption, trapping particles as water flows through the sand bed.

Why Filter Sand Media Is Still Widely Used

Despite the availability of multimedia and specialty filter media, sand remains popular because it offers:

Proven performance over decades

Predictable hydraulic behavior

Compatibility with most filtration designs

Easy availability and cost efficiency

Simple operation and maintenance

When properly selected and operated, filter sand media delivers stable filtration performance with long service life.

How Filter Sand Media Works in a Filtration System

Filtration using sand media is not just surface screening. Removal occurs through multiple mechanisms:

Mechanical Straining – Particles larger than pore spaces are trapped

Sedimentation – Heavier particles settle within the bed

Interception & Adsorption – Fine particles adhere to sand grain surfaces

As filtration progresses, particles accumulate within the bed, increasing pressure drop until backwashing is required.

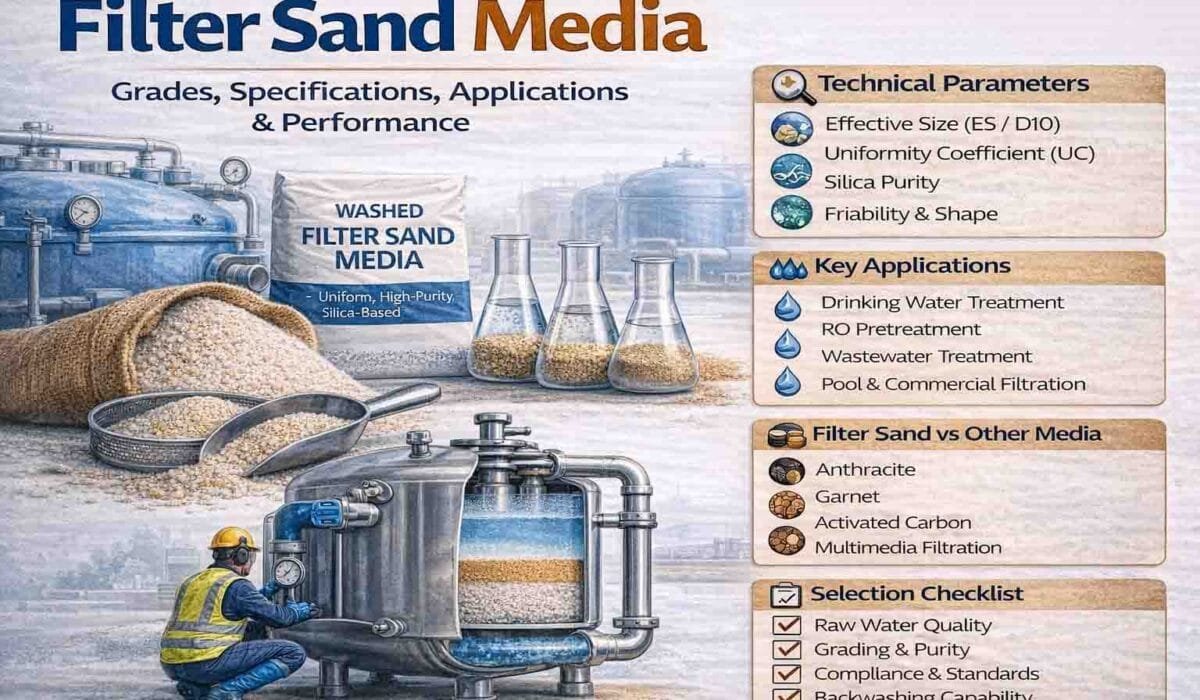

Key Technical Parameters of Filter Sand Media

1. Effective Size (ES / D10)

Effective size (D10) represents the particle diameter at which 10% of the sand is finer.

Smaller ES → finer filtration, higher pressure drop

Larger ES → lower pressure drop, coarser filtration

Correct ES selection is critical for balancing filtration efficiency and filter run time.

2. Uniformity Coefficient (UC)

Uniformity coefficient (UC = D60 / D10) indicates how uniformly graded the sand is.

UC ≤ 1.7 is typically preferred

Lower UC → more uniform flow and backwashing

High UC → risk of channeling and uneven filtration

UC directly impacts hydraulics, backwash efficiency, and media life.

3. Particle Shape and Strength

Filter sand grains should be:

Rounded to sub-angular

Resistant to attrition

Free from friable or flaky particles

Weak grains break down during operation, generating fines that clog the filter bed.

4. Chemical Purity

High-purity silica sand is essential to:

Prevent chemical leaching

Ensure long-term stability

Avoid water quality contamination

Filter sand should be inert across the normal operating pH range.

Common Grades of Filter Sand Media

Filter sand is supplied in different size ranges depending on application:

Fine sand – for low turbidity polishing

Medium sand – for general water treatment

Coarse sand – for high loading or pretreatment

Correct grading ensures:

Uniform flow distribution

Efficient backwashing

Minimal media loss

Applications of Filter Sand Media

1. Municipal Water Treatment

Used in:

Rapid gravity filters

Pressure sand filters

Multimedia filters

Sand removes turbidity, suspended solids, and particulate impurities.

2. Industrial Water Treatment

Applied in:

Process water filtration

Cooling tower makeup water

Boiler feed pretreatment

Sand filters protect downstream equipment and membranes.

3. Wastewater Treatment

Used in:

Tertiary filtration

Effluent polishing

Reuse applications

Sand filters help meet discharge and reuse standards.

4. RO Pretreatment Systems

Filter sand media removes:

Fine suspended solids

Colloidal particles

This reduces fouling of RO membranes and extends membrane life.

5. Swimming Pools & Commercial Filtration

Sand filters provide:

Clear water

Simple operation

Reliable performance

Filter Sand Media vs Other Filter Media

| Media Type | Primary Role |

|---|---|

| Sand | Turbidity & solids removal |

| Anthracite | Depth filtration |

| Garnet | Fine particle removal |

| Activated Carbon | Organics & chlorine |

| Zeolite | Ammonia & fine solids |

Sand often forms the base layer in multimedia filtration systems.

Common Problems Caused by Poor Filter Sand Media

Using incorrect or low-quality sand media leads to:

Sudden pressure drop

Channeling in filter bed

Mud ball formation

Media loss during backwash

Poor water quality

Most filtration failures traced to sand filters are media-related rather than equipment-related.

Filter Sand Media Backwashing Considerations

Proper backwashing is essential to restore performance.

Key factors:

Correct backwash velocity

Adequate bed expansion

Uniform flow distribution

Too little backwash causes clogging; too much causes media loss and breakdown.

Standards Governing Filter Sand Media

Filter sand is commonly specified under:

IS 8419 (India)

AWWA B100 (International)

EN 12904 (Europe)

Each standard defines:

Grading limits

Purity requirements

Physical and chemical properties

Compliance ensures predictable performance and inspection acceptance.

How to Select the Right Filter Sand Media

A proper selection process includes:

Raw water analysis

Target effluent quality

Filtration rate and loading

Backwash system capability

Applicable standards

Sand selection should be application-driven, not price-driven.

When Filter Sand Media Should Be Replaced

Replacement is recommended when:

Grain breakdown becomes significant

Backwashing no longer restores performance

Fines generation increases

Filtration quality deteriorates

Routine inspection and monitoring extend media life.

Why Filter Sand Media Performance Varies Between Suppliers

Two sands may look identical but perform differently due to:

Source mineralogy

Washing quality

Grading accuracy

Quality control consistency

This is why testing, documentation, and batch consistency matter.

Final Thoughts

Filter sand media remains the most important and widely used filtration material in water treatment systems worldwide. Its performance depends not only on design but on correct selection, grading, quality, and operation.

Understanding ES, UC, purity, and application requirements ensures:

Stable filtration

Long media life

Lower operating costs

A sand filter performs only as well as the sand inside it.