Benefits of using Manganese Dioxide for Iron Removal

Manganese dioxide (MnO2) stands out as a preferred choice for water treatment due to its exceptional catalytic prowess and redox capabilities in the removal of iron. Leveraging its active attributes, MnO2 offers a range of benefits in iron removal:

- Efficient Iron Elimination: MnO2 boasts a strong affinity for iron, proficiently extracting both dissolved and precipitated iron from water sources. By oxidizing ferrous iron (Fe2+) into ferric iron (Fe3+), it generates solid particles that are easily filterable.

- Chemical-Free Regeneration: The beauty of MnO2 lies in its catalytic nature, obviating the need for supplementary chemicals during regeneration. As a catalyst, it speeds up iron oxidation without being depleted in the process.

- Durable Performance: With its prolonged lifespan, MnO2 media offers an economical solution for iron removal systems. With regular backwashing and proper upkeep, the media sustains its efficacy over several years.

- Broad pH Adaptability: MnO2’s efficacy spans a wide pH spectrum, typically ranging from 6.2 to 8.8. This adaptability accommodates fluctuations in water acidity and alkalinity, making it adaptable to diverse water sources.

- Foul-Resistance: The media’s catalytic traits and structural design thwart fouling or blockage in the filter bed. This ensures consistent and steady iron removal over time.

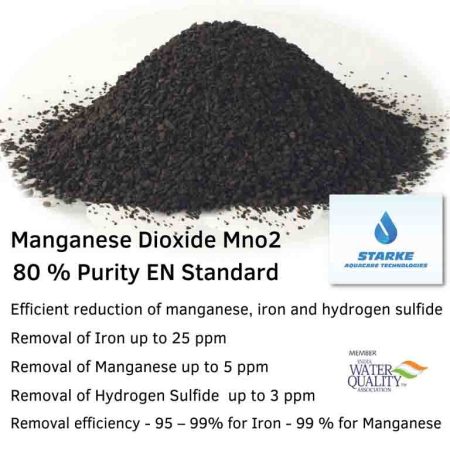

- Holistic Contaminant Purification: Beyond iron, MnO2 extends its purifying influence to other impurities like manganese, hydrogen sulfide (H2S), and specific organics, thus enhancing overall water quality.

- Low Maintenance: MnO2’s minimal need for chemical regeneration translates to reduced maintenance requisites for iron removal systems.

- Eco-Friendly Choice: Embracing MnO2 for iron removal avoids the introduction of harmful chemicals into water, underscoring its eco-friendly water treatment approach.

However, it’s pivotal to recognize that the effectiveness of MnO2 as an iron removal medium hinges on factors such as manganese dioxide purity, water chemistry, flow rates, and the presence of other contaminants. Optimal performance and efficiency require meticulous system design, vigilant monitoring, and consistent maintenance. Furthermore, to prevent depletion and loss of iron removal capacity, regular backwashing and cleaning of MnO2 are imperative.

For seven years, Starke Filter Media has been a trusted exporter of MnO2 to over 11 countries. To delve deeper into the capabilities of our manganese dioxide iron removal media, kindly reach out to us at info@starkefiltermedia.com.